summary

The connection modes of three piece ball valve are very diversified, including internal thread, industrial thick wall pipe welding, butt welding of thin-wall pipe of sanitary pipeline (extended automatic welding can be provided with automatic welding machine), quick installation of sanitary pipeline, sanitary flange of sanitary pipeline, national standard flange of national standard pipeline, etc.

The three piece ball valve body adopts the advanced technology of precision vacuum wax mold casting, with reasonable structure and beautiful shape. The valve seat adopts elastic sealing structure, with reliable sealing and easy opening and closing. The valve rod adopts a bottom mounted structure with inverted seal. When the valve chamber is abnormally pressurized, the valve rod will not be rushed out.

The three piece ball valve body can be equipped with international standard ISO high platform and locking device. It can be equipped with pneumatic actuator, electric actuator, valve position feed, mechanical positioner and intelligent positioner, which can meet the needs of various process automatic control.

Structural features

• the fluid resistance is small, and its resistance coefficient is equal to that of the pipe section with the same length.

• simple structure, small volume and light weight.

• tight and reliable. At present, domestic PTFE and imported PTFE are widely used as the sealing surface materials of ball valves. They have good sealing performance and have been widely used in vacuum systems.

• easy operation and quick opening and closing. It only needs to rotate 90 ° from full opening to full closing.

• easy maintenance, simple structure of ball valve, generally movable sealing ring, and convenient disassembly and replacement.

• when fully open or fully closed, the sealing surface of the ball and valve seat is isolated from the medium. When the medium passes through, it will not cause the erosion of the valve sealing surface.

• sealing characteristics: half package sealing is used in the process without special requirements, and full package sealing structure can be provided for special processes.

Standard specification

• drive mode: manual, with high platform, can be equipped with drive (pneumatic, electric)

• nominal diameter: dn10 ~ DN100 iso12 7 ~ 101.6

• nominal pressure: 1.6Mpa

• applicable temperature: domestic PTFE - 10 ~ 100 ℃, imported PTFE - 10 ~ 150 ℃

• applicable media: gas, water and oil

• drive available: manual, pneumatic and electric

• connection standard: sanitary flange

• valve body material: CF8 (304), CF3 (304L), CF8M (316), cf3m (316L)

Data

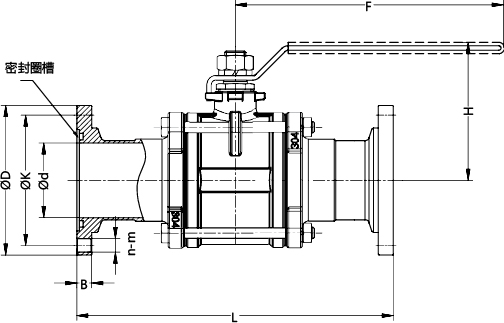

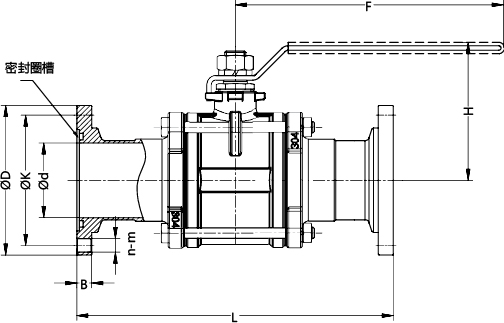

| 配管外径 |

d |

D |

K |

n-m |

L |

B |

H |

F |

| Φ12.7×1.5 |

9.7 |

79 |

67.5 |

4-Φ7 |

120 |

10 |

48 |

95 |

| Φ19.05×1.5 |

16.05 |

79 |

67.5 |

4-Φ7 |

120 |

10 |

55 |

95 |

| Φ25.4×1.5 |

22.4 |

79 |

67.5 |

4-Φ7 |

133 |

10 |

67.5 |

110 |

| Φ31.8×1.5 |

28.8 |

79 |

67.5 |

4-Φ7 |

140 |

10 |

77 |

145 |

| Φ38.1×1.5 |

35.1 |

88 |

75 |

4-Φ7 |

158 |

10 |

83 |

165 |

| Φ50.8×1.5 |

47.8 |

100 |

87.2 |

4-Φ9 |

198 |

10 |

92 |

180 |

| Φ63.5×2 |

59.5 |

114 |

99 |

4-Φ9 |

206 |

10 |

100 |

180 |

| Φ76.2×2 |

72.2 |

130 |

115 |

4-Φ9 |

242 |

11 |

140 |

240 |

| Φ88.9×2 |

84.9 |

140 |

125 |

4-Φ9 |

274 |

11 |

145 |

240 |

| Φ101.6×2 |

97.6 |

162 |

147.5 |

6-Φ9 |

330 |

11 |

170 |

320 |