Product overview

The three-way ball valve is mainly used to realize the flow channel switching function on the premise of cutting off or connecting the medium. The main feature of the square three-way ball valve is to widen the contact surface between the valve body sealing ring and the ball, avoid the small contact surface of the valve body sealing ring of the standard three-way ball valve. In addition, the standard three-way ball valve has no positioning design. When the valve is opened or closed, the ball and the sealing surface are misaligned, resulting in internal leakage and other phenomena, If the cost is not considered in the selection of three-way ball valve, the square three-way ball valve is one of the best ball valves in the three-way process pipeline.

Product features

• the valve body adopts casting, forging and other production processes, and the connection methods include flange, welding, quick assembly, thread and other connection methods.

• the ball core only needs to rotate 90 ° around the valve axis to complete full opening or full closing, with simple and rapid action;

• the sealing ring adopts unique elastic lip sealing technology to ensure the cut-off requirements of zero leakage, and the unique automatic compensation function makes the valve have a longer service life;

• sealing ring materials include PTFE, reinforced PTFE and hard seal, which are suitable for various working conditions.

• after surface hardening treatment, the ball core is smooth and wear-resistant after grinding and polishing;

• the inner diameter of the flow passage is the same as that of the straight through ball type pipe;

• the built-in valve stem has better safety and rigidity;

• because the ball core and sealing ring have shear effect in the switching process, it is especially suitable for pulp, sewage and other slurry fluids with particles;

• anti static devices can be installed according to user requirements;

Sstandard specification

Design and manufacturing standard: GB / t12237-2007

• flange standards: GB / T, JB / T of the Ministry of machinery, Hg / T of the Ministry of chemical industry, API of American Standard, ANSI, din of German standard, JIS of Japanese standard, JPI, BS of British Standard

• structural length standard: GB / t12221-2005

• test and inspection standard: GB / T 13927-2008

• driving mode: manual and configurable driving (pneumatic and electric)

• nominal diameter: DN15 ~ DN100 iso19 05 ~ 101.6

• nominal pressure: 1.0MPa

• applicable temperature: domestic PTFE - 10 ~ 100 ℃, imported PTFE - 10 ~ 150 ℃

• applicable media: gas, water and oil

• it can be equipped with drive: manual, electric, pneumatic and hydraulic

• connection standard: quick installation

• valve body material: CF8 (304), CF3 (304L), CF8M (316), cf3m (316L)

Materials of main parts

| 阀体 |

WCB |

ZG1Cr18Ni9Ti |

CF8 |

CF3 |

ZG1Cr18Ni12Mo2Ti |

CF8M |

CF3M |

| 球体 阀杆 |

1Cr13 |

1Cr18Ni9Ti |

304 |

304L |

1Cr18Ni12Mo2Ti |

316 |

316L |

| 阀座 |

聚四氟乙烯PTFE加坡纤增强聚四氟乙烯PTFE+Glass 对位聚笨PPL |

| 垫片 |

聚四氟乙烯PTFE不锈钢/柔性石墨 |

| 阀杆座 |

聚四氟乙烯PTFE不锈钢/柔性石墨 |

| 填料 |

聚四氟乙烯PTFE增强柔性石墨 |

| 填料压盖 |

WCB |

1Cr18Ni9Ti |

304 |

304L |

1Cr18Ni12Mo2Ti |

316 |

316L |

| 温度 |

国产PTFE -10~100℃

进口PTFE -10~100℃ |

| 介质 |

水、蒸汽、油品 |

硝酸类 |

强氧化介质 |

醋酸类 |

尿素类 |

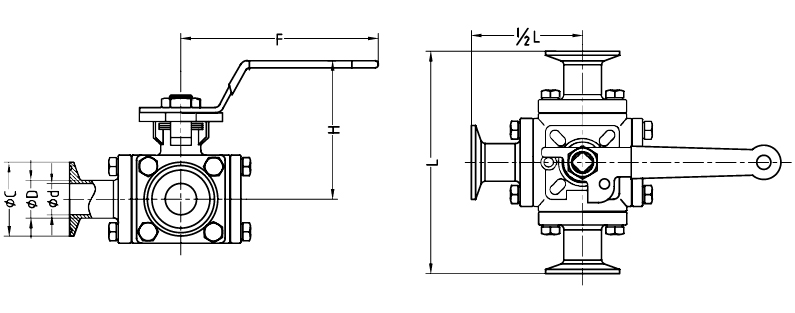

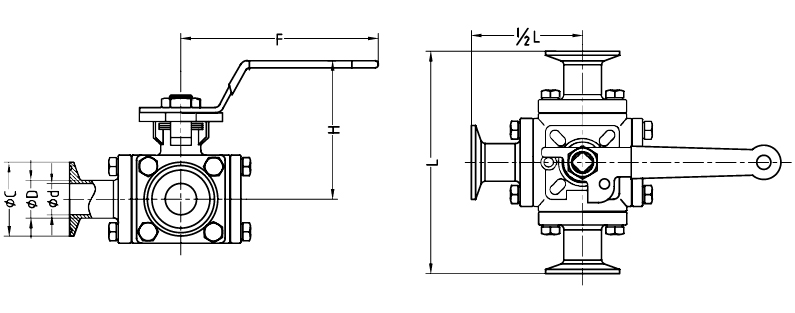

Data

Series of DIN / a series of DIN

| 规格 |

D |

d |

C |

L |

F |

H |

| DN15 |

19×1.5 |

16 |

34/50.5 |

118 |

135 |

77 |

| DN20 |

23×1.5 |

20 |

34/50.5 |

127 |

135 |

78 |

| DN25 |

28×1.5 |

25 |

50.5 |

152 |

135 |

95 |

| DN32 |

34×1.5 |

31 |

50.5 |

175 |

181 |

113 |

| DN40 |

40×1.5 |

37 |

50.5 |

175 |

181 |

113 |

| DN50 |

53×1.5 |

50 |

64 |

201 |

181 |

121 |

| DN65 |

70×2 |

66 |

91 |

227 |

181 |

135 |

| DN80 |

85×2 |

81 |

106 |

262 |

336 |

140 |

| DN100 |

104×2 |

100 |

119 |

319 |

436 |

158 |

Second series ISO

| 规格 |

D |

d |

C |

L |

F |

H |

| 3/4" |

19.05×1.5 |

15.8 |

34/50.5 |

127 |

135 |

78 |

| 1" |

25.4×1.5 |

22.1 |

50.5 |

152 |

135 |

95 |

| 1.25" |

31.8×1.5 |

28.5 |

50.5 |

175 |

181 |

113 |

| 1.5" |

38.1×1.5 |

34.8 |

50.5 |

175 |

181 |

113 |

| 2" |

50.8×1.5 |

47.5 |

64 |

201 |

181 |

121 |

| 2.5" |

63.5×1.5(2) |

60.5 (59.5) |

77.5 |

227 |

181 |

135 |

| 3" |

76.2×2 |

72.9 |

91 |

262 |

336 |

140 |

| 3.5" |

88.9×2 |

84.9 |

106 |

262 |

336 |

140 |

| 4" |

101.6×2 |

97.4 |

119 |

319 |

436 |

158 |