Product overview

The three-way flange ball valve is mainly used to realize the channel switching function on the premise of cutting off or connecting the medium.

Product features

• the fluid resistance is small. The ball valve has the smallest fluid resistance among all valves. Even the reduced diameter ball valve has very small fluid resistance.

• the switch is quick and convenient. As long as the valve stem rotates 90 °, the ball valve will complete the full opening or full closing action, which is easy to realize rapid opening and closing.

• good sealing performance. The sealing ring of ball valve seat is generally made of PTFE and other elastic materials, which is easy to ensure sealing.

• reliable valve stem sealing. When the ball valve is opened and closed, the valve stem only rotates, so the packing seal of the valve stem is not easy to be damaged.

• the opening and closing of the ball valve only rotates 90 °, so it is easy to realize automatic control and remote control. It can be equipped with pneumatic actuator and electric actuator.

Standard specification

Design and manufacturing standard: GB / t12237-2007

• flange standards: GB / T, JB / T of the Ministry of machinery, Hg / T of the Ministry of chemical industry, API of American Standard, ANSI, din of German standard, JIS of Japanese standard, JPI, BS of British Standard

• structural length standard: GB / t12221-2005

• test and inspection standard: GB / T 13927-2008

• driving mode: pneumatic drive

• nominal diameter: DN15 ~ DN300

• nominal pressure: 1.6Mpa, 2.5MPa, 4.0Mpa

• applicable temperature: domestic PTFE - 10 ~ 100 ℃, imported PTFE - 10 ~ 150 ℃, optional cemented carbide seal (can be equipped with ball nitriding process,

The temperature can withstand 350 ℃, equipped with ball hard chromium plating Ni60 process, the temperature can withstand 500 ℃)

• applicable media: gas, water and oil

• it can be equipped with drive: manual, electric, pneumatic and hydraulic

• production standard: GB / t12237-2007

• valve body material: cast steel, CF8 (304), CF3 (304L), CF8M (316), cf3m (316L)

Materials of main parts

| 阀体 |

WCB |

ZG1Cr18Ni9Ti |

CF8 |

CF3 |

ZG1Cr18Ni12Mo2Ti |

CF8M |

CF3M |

| 球体 阀杆 |

1Cr13 |

1Cr18Ni9Ti |

304 |

304L |

1Cr18Ni12Mo2Ti |

316 |

316L |

| 阀座 |

聚四氟乙烯PTFE加坡纤增强聚四氟乙烯PTFE+Glass 对位聚笨PPL |

| 垫片 |

聚四氟乙烯PTFE不锈钢/柔性石墨 |

| 阀杆座 |

聚四氟乙烯PTFE不锈钢/柔性石墨 |

| 填料 |

聚四氟乙烯PTFE增强柔性石墨 |

| 填料压盖 |

WCB |

1Cr18Ni9Ti |

304 |

304L |

1Cr18Ni12Mo2Ti |

316 |

316L |

| 温度 |

国产PTFE -10~100℃

进口PTFE -10~100℃ |

| 介质 |

水、蒸汽、油品 |

硝酸类 |

强氧化介质 |

醋酸类 |

尿素类 |

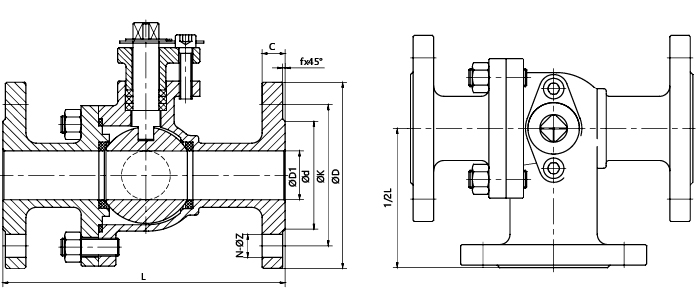

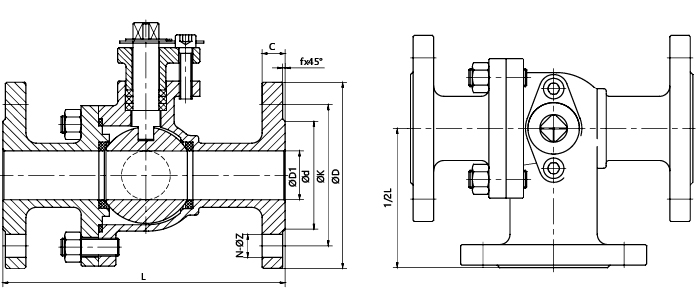

Data

| DN |

D1 |

d |

K |

D |

f |

C |

N-ΦZ |

L |

| 15 |

15 |

45 |

65 |

95 |

2 |

14 |

4-Φ14 |

150 |

| 20 |

20 |

55 |

75 |

105 |

2 |

14 |

4-Φ14 |

160 |

| 25 |

25 |

65 |

85 |

115 |

2 |

14 |

4-Φ14 |

180 |

| 32 |

32 |

78 |

100 |

135 |

2 |

16 |

4-Φ18 |

200 |

| 40 |

40 |

85 |

110 |

145 |

2 |

16 |

4-Φ18 |

220 |

| 50 |

50 |

100 |

125 |

160 |

2 |

16 |

4-Φ18 |

240 |

| 65 |

65 |

120 |

145 |

180 |

2 |

18 |

4-Φ18 |

260 |

| 80 |

80 |

135 |

160 |

195 |

2 |

20 |

8-Φ18 |

280 |

| 100 |

100 |

155 |

180 |

215 |

2 |

20 |

8-Φ18 |

320 |

| 125 |

125 |

185 |

210 |

245 |

2 |

22 |

8-Φ18 |

380 |

| 150 |

150 |

210 |

240 |

280 |

2 |

24 |

8-Φ22 |

440 |

| 200 |

200 |

265 |

295 |

335 |

2 |

26 |

12-Φ22 |

550 |

| 250 |

250 |

320 |

355 |

405 |

2 |

26 |

12-Φ26 |

670 |

| 300 |

300 |

375 |

410 |

460 |

2 |

28 |

12-Φ26 |

720 |