Product overview

Q41F-16PManual floating ball valve is mainly used to cut off or connect the medium, and can also be used for fluid regulation and control

Product features

• the valve body adopts casting, forging and other production processes, and the connection methods include flange, welding, quick assembly, thread and other connection methods.

• the ball core only needs to rotate 90 ° around the valve axis to complete full opening or full closing, with simple and rapid action;

• the sealing ring adopts unique elastic lip sealing technology to ensure the cut-off requirements of zero leakage, and the unique automatic compensation function makes the valve have a longer service life;

• sealing ring materials include PTFE, reinforced PTFE and hard seal, which are suitable for various working conditions.

• after surface hardening treatment, the ball core is smooth and wear-resistant after grinding and polishing;

• the inner diameter of the flow passage is the same as that of the straight through ball type pipe;

• the built-in valve stem has better safety and rigidity;

• because the ball core and sealing ring have shear effect in the switching process, it is especially suitable for pulp, sewage and other slurry fluids with particles;

• anti static devices can be installed according to user requirements;

standard specification

Design and manufacturing standard: GB / t12237-2007

• flange standards: GB / T, JB / T of the Ministry of machinery, Hg / T of the Ministry of chemical industry, API of American Standard, ANSI, din of German standard, JIS of Japanese standard, JPI, BS of British Standard

• structural length standard: GB / t12221-2005

• test and inspection standard: GB / T 13927-2008

• driving mode: manual driving

• nominal diameter: DN15 ~ DN300

• nominal pressure: 1.6Mpa, 2.5MPa, 4.0Mpa, 6.4Mpa

• applicable temperature: domestic PTFE - 10 ~ 100 ℃, imported PTFE - 10 ~ 150 ℃, optional cemented carbide seal (can be equipped with ball nitriding process,

The temperature can withstand 350 ℃, equipped with ball hard chromium plating Ni60 process, the temperature can withstand 500 ℃)

• applicable media: gas, water and oil

• can be equipped with drive: electric, pneumatic, hydraulic

• production standard: GB / t12237-2007

• valve body material: cast steel, CF8 (304), CF3 (304L), CF8M (316), cf3m (316L)

Materials of main parts

| 阀体 |

WCB |

ZG1Cr18Ni9Ti |

CF8 |

CF3 |

ZG1Cr18Ni12Mo2Ti |

CF8M |

CF3M |

| 球体 阀杆 |

1Cr13 |

1Cr18Ni9Ti |

304 |

304L |

1Cr18Ni12Mo2Ti |

316 |

316L |

| 阀座 |

聚四氟乙烯PTFE加坡纤增强聚四氟乙烯PTFE+Glass 对位聚笨PPL |

| 垫片 |

聚四氟乙烯PTFE不锈钢/柔性石墨 |

| 阀杆座 |

聚四氟乙烯PTFE不锈钢/柔性石墨 |

| 填料 |

聚四氟乙烯PTFE增强柔性石墨 |

| 填料压盖 |

WCB |

1Cr18Ni9Ti |

304 |

304L |

1Cr18Ni12Mo2Ti |

316 |

316L |

| 温度 |

国产PTFE -10~100℃

进口PTFE -10~100℃ |

| 介质 |

水、蒸汽、油品 |

硝酸类 |

强氧化介质 |

醋酸类 |

尿素类 |

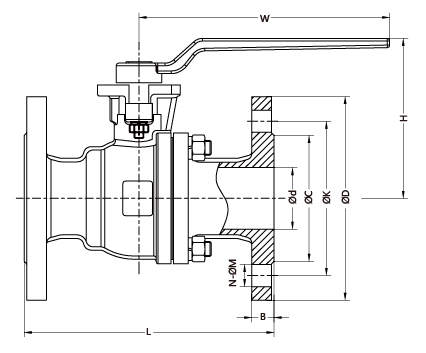

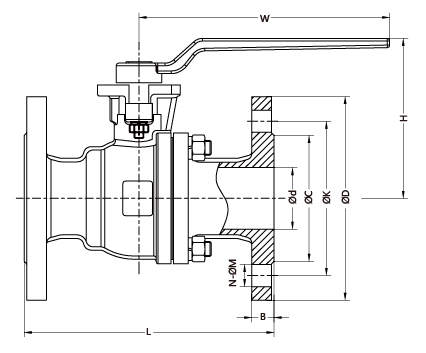

Data

| 规格 |

d |

L |

D |

K |

C |

B |

Z-ΦM |

H |

W |

| DN15 |

15 |

130 |

95 |

65 |

45 |

16 |

4-Φ14 |

75 |

110 |

| DN20 |

20 |

130 |

105 |

75 |

58 |

18 |

4-Φ14 |

77 |

130 |

| DN25 |

25 |

140 |

115 |

85 |

68 |

18 |

4-Φ14 |

85 |

150 |

| DN32 |

32 |

165 |

140 |

100 |

78 |

18 |

4-Φ18 |

97 |

190 |

| DN40 |

40 |

165 |

150 |

110 |

88 |

18 |

4-Φ18 |

103 |

200 |

| DN50 |

50 |

203 |

165 |

125 |

102 |

18 |

4-Φ18 |

115 |

220 |

| DN65 |

65 |

222 |

185 |

145 |

122 |

18 |

8-Φ18 |

140 |

230 |

| DN80 |

80 |

241 |

200 |

160 |

138 |

20 |

8-Φ18 |

165 |

280 |

| DN100 |

100 |

305 |

220 |

180 |

158 |

20 |

8-Φ18 |

190 |

280 |

| DN125 |

125 |

320/356 |

250 |

210 |

188 |

22 |

8-Φ18 |

215 |

320 |

| DN150 |

150 |

360/394 |

285 |

240 |

212 |

22 |

8-Φ22 |

250 |

360 |

| DN200 |

200 |

400/457 |

340 |

295 |

268 |

24 |

12-Φ22 |

295 |

1000 |