A fire-safe and anti-static ball valve is designed for pipelines transporting natural gas, synthetic coal gas, liquefied petroleum gas (LPG), city gas, and non-corrosive gases. It incorporates anti-static and fire-safe mechanisms:

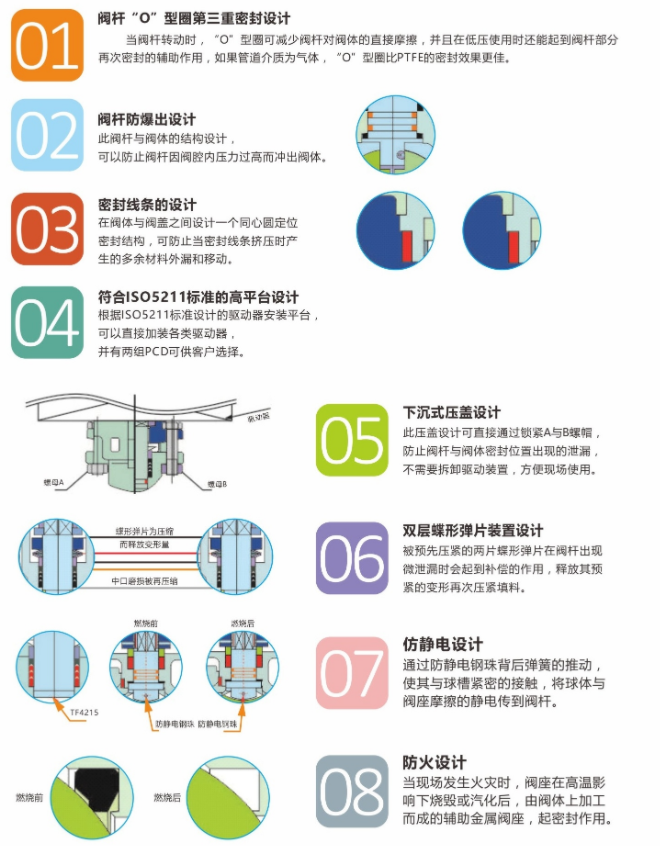

Anti-static design: Conductive springs are installed between the ball and valve stem and between the stem and valve body, creating an electrostatic discharge path to channel static electricity generated during valve operation into the pipeline and ground, eliminating electrostatic hazards.

Fire-safe design: Dual sealing layers are employed. If the soft seal (e.g., PTFE) melts under high temperatures, the ball rotates to form a secondary metal-to-metal seal at a right-angle backup seat, maintaining sealing integrity.

Safety Performance

Fire-safe valves: Widely used in high-risk industries (e.g., oil, gas, chemicals), they prevent internal leakage during fires. The dual-seal design—soft seal + metal seal—ensures that if the soft seal is destroyed by flames, the metal seal provides backup containment, reducing media leakage and fire spread.

Standard valves: Lack redundant sealing systems, posing higher risks in flammable environments.

Anti-Static Mechanism

Fire-safe valves: Equipped with an electrostatic discharge device to rapidly dissipate static charges accumulated on the ball during operation. This prevents spark-induced explosions in gas, fuel, or chemical pipelines.

Standard valves: No built-in anti-static features, risking electrostatic discharge in sensitive applications.

Technical Standards

Fire-safe valves: Follow strict resistance requirements. The electrical resistance between the ball/valve body and stem/ball must be **≤10 ohms under 12V DC**, typically achieved through elastic component connections (e.g., springs).

Standard valves: No such specifications unless customized for hazardous environments.